Description

Ball Bearing Drawer Slides Manufacturer

Key Points of Professional Ball Bearing Slide Manufacturer

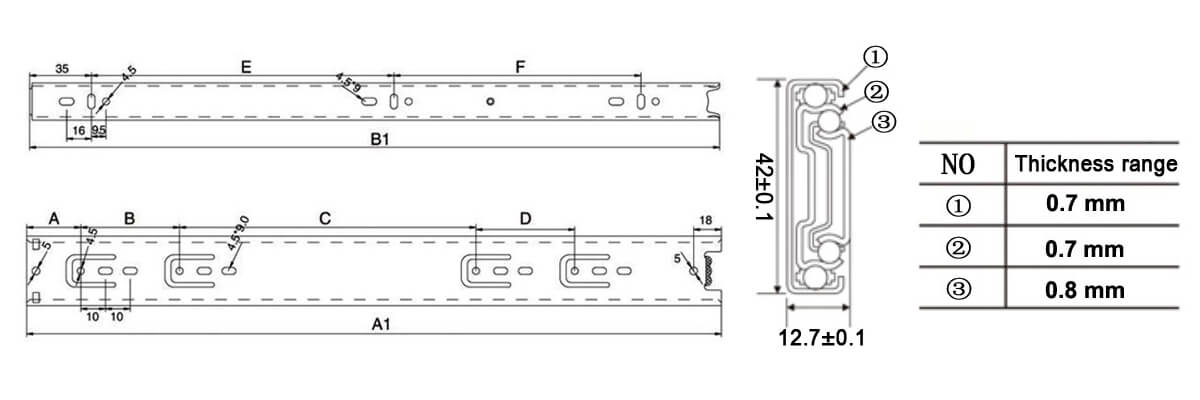

SKU | Size | A1(mm) | B1(mm) | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | F(mm) |

44.41.00104312 | 12” | 300 | 297 | 35 | 64 | 128 | — | 96 | 128 |

44.41.00104314 | 14” | 350 | 347 | 35 | 64 | 96 | 64 | 128 | 128 |

44.41.00104316 | 16” | 400 | 397 | 35 | 64 | 160 | 64 | 160 | 160 |

44.41.00104318 | 18” | 450 | 447 | 35 | 64 | 192 | 64 | 160 | 192 |

44.41.00104320 | 20” | 500 | 497 | 35 | 64 | 256 | 64 | 192 | 224 |

44.41.00104322 | 22” | 550 | 547 | 35 | 64 | 288 | 64 | 224 | 224 |

44.41.00104324 | 24” | 600 | 597 | 35 | 64 | 352 | 64 | 224 | 288 |

SKU | Pairs/ | Net Weight | Gross Weight | Package Size | PCS/ | PCS/ | PCS/ |

44.41.00104312 | 20 | 22.71lbs / 10.3kg | 23.15lbs / 10.5kg | 315 * 180 * 135 | 30240 | 43200 | 47520 |

44.41.00104314 | 20 | 26.46lbs / 12kg | 26.90lbs / 12.2kg | 365 * 180 * 135 | 25200 | 36000 | 39600 |

44.41.00104316 | 20 | 31.97lbs / 14.5kg | 32.41lbs / 14.7kg | 415 * 180 * 135 | 20160 | 28800 | 31680 |

44.41.00104318 | 20 | 36.16lbs / 16.4kg | 36.60lbs / 16.6kg | 465 * 180 * 135 | 20160 | 25920 | 28800 |

44.41.00104320 | 20 | 39.46lbs / 17.9kg | 39.90lbs / 18.1kg | 515 * 180 * 135 | 16800 | 24000 | 26400 |

44.41.00104322 | 20 | 41.67lbs / 18.9kg | 42.11lbs / 19.1kg | 565 * 180 * 135 | 16800 | 24000 | 26400 |

44.41.00104324 | 20 | 45.52lbs / 20.65kg | 45.97lbs / 20.85kg | 615 * 180 * 135 | 14400 | 21600 | 21600 |

How do undermount drawer slides work

The basic function of the fixed element (guide rail) of the linear guide system is like a bearing ring, a bracket for installing the steel ball, and the shape is a “U” shape. The bracket wraps around the top and sides of the rail. To support the drawers, a set of linear guides has at least four brackets. For supporting large working parts, the number of brackets can be more than four.

When the drawer moves, the steel balls circulate in the groove of the bracket, and the wear of the bracket is distributed to each steel ball, thereby prolonging the service life of the linear guide. In order to eliminate the gap between the bracket and the guide rail, the preload can improve the stability of the guide rail system, and the preload can be obtained. It is to install an oversized steel ball between the rail and the bracket. The diameter tolerance of the steel balls is ±20 microns, and the steel balls are screened and classified in increments of 0.5 microns and installed on the guide rails respectively. The size of the preload depends on the force acting on the steel balls. If the force acting on the steel ball is too large and the preload time is too long, the movement resistance of the bracket will increase, and there will be a balance problem; in order to improve the sensitivity of the system and reduce the movement resistance, the preload should be reduced accordingly. , and in order to improve the motion accuracy and accuracy retention, it is required to have enough pre-added negative numbers, which are two contradictory aspects.

If the working time is too long, the steel ball begins to wear out, and the preload acting on the steel ball begins to weaken, resulting in the reduction of the movement accuracy of the outer rail. If the original accuracy is to be maintained, the rail brackets must be replaced, or even the rails. If the rail system is already preloaded. System accuracy has been lost and the only way to do it is to replace the rolling elements.

The design of the guide rail system strives to have the largest contact area between the fixed element and the moving element, which can not only improve the bearing capacity of the system, but also the system can withstand the impact force generated by intermittent cutting or gravity cutting, spread the force widely, and expand the bearing capacity. area of force. In order to achieve this, there are various groove shapes for the rail system, there are two representative ones, one is called Gothic (pointed arch), the shape is an extension of a semicircle, and the contact point is the vertex; the other The species is arc-shaped and can also play the same role. No matter what kind of structure, the purpose is only one, and strive to make more rolling steel ball radius in contact with the guide rail (fixed element). What determines the performance characteristics of the system is how the rolling elements come into contact with the guide rails, which is the crux of the matter.

Classification of undermount drawer slides

Undermount drawer slides can be divided into heavy-duty slides and light-duty slides according to the bearing weight. The material, it can be divided into carbon steel slides and stainless steel slides. According to the installation method, it can be divided into side-mounted slides and bottom-mounted slides. According to the temperature, it can be divided into normal temperature slides and high-temperature resistant slides. In the past, the drawer was not installed with slides, and the drawer would tilt downward, pull out smoothly, and easily fall off and hurt people. In order to solve this problem, the slide rail came into being. Its features such as smooth push and pull, strong bearing capacity, safety and beauty, and easy installation are quickly applied to the furniture industry. Later, because the slide can solve the lack of space and save space, it is widely used in industrial automation, mechanical equipment, and special equipment.

Why you need to care about the finished undermount drawer slides

Choosing the right metal finish isn’t just about color and home decor. It is also a complex process, and different choices will affect function and longevity.

Most of the corrosion of metal materials occurs in the atmospheric environment, which contains corrosive components and factors such as oxygen, humidity, temperature changes, and pollutants. Salt spray corrosion is a common and destructive atmospheric corrosion.

The corrosion of metal materials by salt spray is mainly because the conductive salt solution penetrates into the metal and undergoes an electrochemical reaction, forming a “low-potential metal-electrolyte solution-high-potential impurity” micro-battery system, electron transfer occurs, and the metal as the anode dissolves, The formation of new compounds known as corrosion products. Chloride ion plays a major role in the process of salt spray corrosion damage. It has a strong penetrating ability and can easily penetrate the metal oxide layer and enter the interior of the metal, destroying the passive state of the metal; at the same time, chloride ion has small hydration energy, It is easily adsorbed on the metal surface and replaces the oxygen in the oxide layer that protects the metal, causing the metal to be damaged.

Pros and cons of undermount drawer slides

Undermount drawer slides have a mixed friction state with a certain dynamic pressure effect. The dynamic pressure effect of the guide rail is mainly related to the friction speed of the guide rail, the viscosity of the lubricating oil, and the size and type of the oil groove on the guide rail surface. For the main motion guide rail with high speed, the type and size of the oil groove should be reasonably designed, and the lubricating oil of suitable viscosity should be selected to produce a better dynamic pressure effect.

The advantages are simple structure, convenient manufacture, and good vibration resistance.

The disadvantage is that it wears out quickly.

How to install undermount drawer slides

Select the appropriate length and size;

The conventional drawer buffer slides are 250-600mm long (10-24 inches), the common ones are 15 inches, 18 inches, 21 inches, the selected slide rail must be shorter than the depth of the drawer, but the deviation cannot be too large, the lighter the drawer, The shorter the slide rail, the less obvious the buffering effect is. The buffer slide rail is the most suitable for drawers with a depth of 350-450mm.

The installation clearance must be accurate;

The thickness of the general three-section undermount drawer slides is 12.7-13mm. In order to reduce the cost, some factories choose 0.9mm or even 0.8mm thick plates. Naturally, the thickness of the slide rails has also changed, and the installation gap must be determined according to the actual object.

Horizontally fix the inner and outer rails of the undermount drawer slides;

The level of installation of undermount drawer slides is much higher than that of ordinary three-section slide rails. Not only must the inner and outer rails on one side be on the same level, but also the slide rails on both sides must be at the same level, otherwise it will not only affect the opening of the drawer smoothness, and may damage the undermount drawer slides.

- Align the ports of the inner rails on both sides of the drawer side panel with the ports of the middle rail, and then gently push it in, you will hear a light “click”, indicating that the movable rail and the fixed rail have been linked, and the drawer You can push and pull freely.

Undermount drawer slides on the sale market

There are many brands on the market, and many of them are imported from China,

Blum undermount drawer slide, Accuride undermount drawer slides, grass undermount drawer slides, Salice undermount drawer slides, DTC undermount drawer slides, Hettich undermount drawer slides, rockler undermount drawer slides.

Venace is a professional OEM manufacturer providing custom undermount drawer slides for importers and distributors, welcome send us a quote!

Frequently asked questions

1. Are you undermount drawer slide manufacturer?

Yes, we are undermount drawer slide manufacturer in Guangzhou, Guangdong China with more than 80000 square meters.

2. Can we use our LOGO and package design?

Yes, OEM is acceptable. We can provide the best OEM service for you.

3. What’s the sample cost?

According to the product price, some can be free, you are responsible for the courier fee. (DHL, TNT, FEDEX)

4. What’s the payment term?

Normally TT(30% deposit), D/P, L/C, Alipay.

5. What’s the lead time for mass production?

Normally 30 days after deposit, We will discuss the order plan with you in detail, including the follow-up order cooperation plan, and guarantee on-time delivery for you.

Reviews

There are no reviews yet.