Things You Need to Know About Gas Springs

Introduction

Gas springs are commonly used as a return force to hold two opposing windows or doors together in both commercial and residential buildings. Gas springs can be used in these applications because of the simplicity of their design, the reliability they have, and their cost-efficiency.

In this article, there will be an understanding of how gas springs work, what kinds of gas springs are available; which ones are likely to be applicable for use on applications such as a window/door system; and other information about application examples that use gas springs.

How it Works:

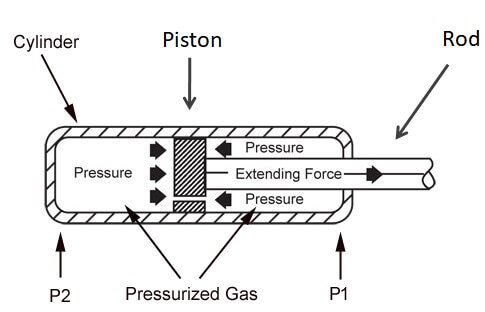

The mechanism behind a gas spring is basic physics (An online resource). A cylinder with pistons attached has more stored energy than one with no compression when placed under compression. When a force, applied to the piston end, pushes down on the piston and cylinder, depleting the compressed gas stored within. The other end of the cylinder is attached to a spring mounting which can be mounted onto another component or completely stand-alone. When released from compression, springs return due to elasticity.

Different Types:

There are many types of gas springs available; some have more specific purposes than others do. Below are examples of common applications for gas springs in both residential buildings and commercial skyscrapers:

- A) Simple Gas Spring: a simple gas spring is most commonly used to hold two opposing doors together or can be placed on any moving part on a door that requires constant force, so the door may function properly. An example of this type of application would be if one person was pulling the door open while another was pushing it closed; there are many factors that must go into effect for everything to function accordingly. A simple gas spring can also be used as an undercarriage suspension system on vehicles when springs begin to wear out from use.

- B) Heavy Duty Gas Spring:The heavy-duty gas spring is much stronger than the simple type and best applied in instances where extra reinforcement is needed. When buildings become physically larger and taller than observation decks require extra support for safety measures,

- C) Long Travel Gas Spring: These springs are used in situations where a larger degree of travel is needed for an object. An example would be when windows need to open up from the bottom out instead of just sliding horizontally or vertically as all other windows do.

- D) High-Performance Gas Spring: This type of gas spring is typically categorized by how fast it can apply force and consume energy. The high-performance gas spring has become relevant to modern technology because it can operate much faster than any mechanical system ever created, producing a consistent flow of energy without tying it down to one specific function. Modern vehicles rely on this type of technology due to its high adaptability that allows support but can change direction and function as needed.)

- E) Multi-Spring System:A multi-spring system combines two or more gas springs bundled into one unit. This spring type is mostly used in industrial and automotive fields for extreme conditions that require extra support.

What it looks like

-

Simple Gas Spring

A Simple Gas Spring consists of 3 main components: the cylinder head cover, the cylinder head, and the piston. The piston is connected to a rod that has a ball mounted at one end and a swivel-type joint with an attached hook on the other. The ball joint allows for 360-degree movement while in use; this connection can attach to anything that stretches. While pushing down on the top of the cylinder, the cover forces gas into the piston chamber from below through an open valve. (This system works as if you were pumping up your bicycle tire.) As force is applied to compress the gas, more stored energy increases in the spring, which returns when released. A simple spring can produce 100-200 pounds per inch of travel with relatively fast response times; most systems take only less than a second to return. The heavy-duty spring can produce even more force with higher travel and slower response time. This is because larger diameter gas springs are needed to compensate for the additional weight that this system would have to carry in order to meet demanding loads; heavier loads require more energy and thus will need a stronger spring.

-

Long Travel Gas Spring

A Long Travel Gas Spring has similar components as the Simple Gas Spring, except that the piston has different joints attached where it attaches to its rod. In this case, one end has an elbow joint while another end is mounted with a ball joint so it can be fitted onto virtually any length of piping without obstruction.

-

A High-Performance Gas Spring

A High-Performance Gas Spring has additional parts but functions similarly to other springs: It uses stored energy that becomes available for use when compressed. The valves are opened manually to control the amount of gas released into the system; this process can be used with any type of spring using anything from the solid rod, wire mesh, fabric, or metal.

The components of this high-performance model consist of two cylinders with a piston for each and two covers. Covers are gas springs in themselves; pistons connect with the inner side of the cylinder cover. The outer sides of the cylinder covers have openings to allow compressed air or nitrogen (not shown) to flow into their respective chambers.

The only difference between this high-performance spring and a simple spring is that this design has an additional pilot valve that works along with its external cylinder cover. This function allows control over how much-stored energy will be available for use at a given time; when activated by pushing down on its cylindrical head, it opens a valve via internal mechanism as if operating with any other type of spring system.

The gas spring is designed for high performance; the body of each cylinder can rotate 360 degrees on a center bolt, and the outer sides of covers are equipped with opening doors. A pilot valve is used to maintain pressure in an air or nitrogen chamber within its cylinder while being compressed by pushing down on top of its head, which opens up a valve that releases the stored energy when given back some space. (Energy is released by allowing compressed air/nitrogen to flow into the piston chamber.)

When pushed down again, all three locking mechanisms will drop back into their respective openings at once, just as they were when first opened. All openings on this model must be closed properly so the spring can function properly: the two-cylinder covers and the piston cover. The pressure of gas keeps these parts locked in place during operation but acts as a safety precaution so a user cannot be hurt if there happens to be an emergency with this type of product.